Fuel Dispensers

In 2015 APLMF agreed to summarise the test procedures used in each APLMF training course and then to survey its members to validate the test procedures and to provide some quality control. The validated test procedures will be later used to develop eLearning modules.

The summary test procedures are provided to guide economies wishing to follow OIML recommendations. They contain abbreviated terms and formulae which are defined in the relevant OIML recommendation.

Information relating to fuel dispensers:

The summary test procedures are provided to guide economies wishing to follow OIML recommendations. They contain abbreviated terms and formulae which are defined in the relevant OIML recommendation.

Information relating to fuel dispensers:

SUMMARY OF TEST PROCEDURES USED TO VERIFY FUEL DISPENSERS

- These test procedures are based on OIML R 117.

- Please note tests used to compile this summary are fully described in the document 5.1 NITP Verification of Fuel Dispensers.

Test Name |

Procedures Description |

VISUAL INSPECTION |

|

CHECKING FACILITY FOR ELECTRONIC INDICATORS |

Visually check the entire electronic display by:

|

ZERO SETTING FOR MECHANICAL RESET MECHANISM ZERO SETTING FOR ELECTRONIC RESET MECHANISM |

|

PRICE COMPUTING |

|

NOZZLE CUT-OFF |

|

INTERLOCK HOSES SHARING A COMMON INDICATOR |

|

INTERLOCK HOSES SHARING A COMMON PUMPING UNIT |

|

PRE-SET INDICATIONS |

|

MAXIMUM FLOW RATE HOSES SHARING A COMMON PUMPING UNIT* *Only performed at initial verification, or when any site changes occur. |

|

ACCURACY |

|

ACCURACY OF PRE-SET |

|

GAS ELIMINATION |

|

ANTI-DRAIN / HOSE DILATION WITHOUT A HOSE REEL |

|

ANTI-DRAIN / HOSE DILATION WITH A HOSE REEL |

|

SUMMARY OF ECONOMY REPORTS

Presented at the training course in Pattaya City, Thailand 15-19 June 2015 and 11-13 July 2016

Economy |

Legislation |

SI |

MPE used |

Inspector or 3rd party |

Verification periods |

Australia |

Yes |

Yes |

±0.3% |

3rd party |

None |

Cambodia |

Yes |

Yes |

±0.5% initial, ±1% subsequent |

municipal and provincial staff, Inspector |

1 Year |

China |

Yes |

Yes |

±0.3% (0.15% repeatability) |

Inspectors |

6 month |

Indonesia |

Yes |

Yes |

±0.5% |

Inspectors, Regional responsibility |

1 Year |

Malaysia |

Yes |

Yes |

±0.5% |

Private company Metrology Corporation of Malaysia Verification officers |

1 Year |

Mongolia |

Yes |

Yes |

±0.25% |

Inspectors |

6 months |

Paupa-New Guinea |

Yes (ICCC is regulator) |

Yes |

±0.5% but we only check Price only |

Inspectors |

1 Year |

Philippines |

Yes |

Yes |

±0.5% |

3rd PARTY with inspectors observing and marking. Local government NML |

2 Months |

Thailand |

Yes |

Yes |

±0.5% |

Inspectors/manufacturers with license |

2 Y (inspector) 60 days (repairer) |

Viet Nam |

Yes |

Yes |

±0.3% |

Verifiers who are certified and licensed |

1 Year |

Economy |

OIML compliant |

Type approval |

Issues |

Other |

Australia |

Yes |

Yes |

- |

- |

Cambodia |

Yes |

Manufacturer |

HR, equipment, primary, secondary for WB or working standards, WB unit, Public awareness, Law enforcement, software, budget |

More training and equipment |

China |

Yes |

Yes |

Software for cheating, compulsory |

- |

Indonesia |

Yes, not fully adopted |

Yes, not all tests |

Electronic disturbance, influence factors, need facilities |

- |

Malaysia |

Yes |

Yes |

Capacity building for new inspectors- |

- |

Mongolia |

Yes |

No |

- |

- |

Paupa-New Guinea |

Yes |

No |

HR, Budget, Basic equipment, conflict between regulators |

Do not calibrate |

Philippines |

Not yet working towards - only accuracy test |

No |

LGU lack knowledge to verify, equipment not compliant |

- |

Thailand |

Yes |

No |

Low # weights and measures officers |

- |

Viet Nam |

Yes |

Yes |

absence of regulation for repairers, No regulation regarding maintenance |

- |

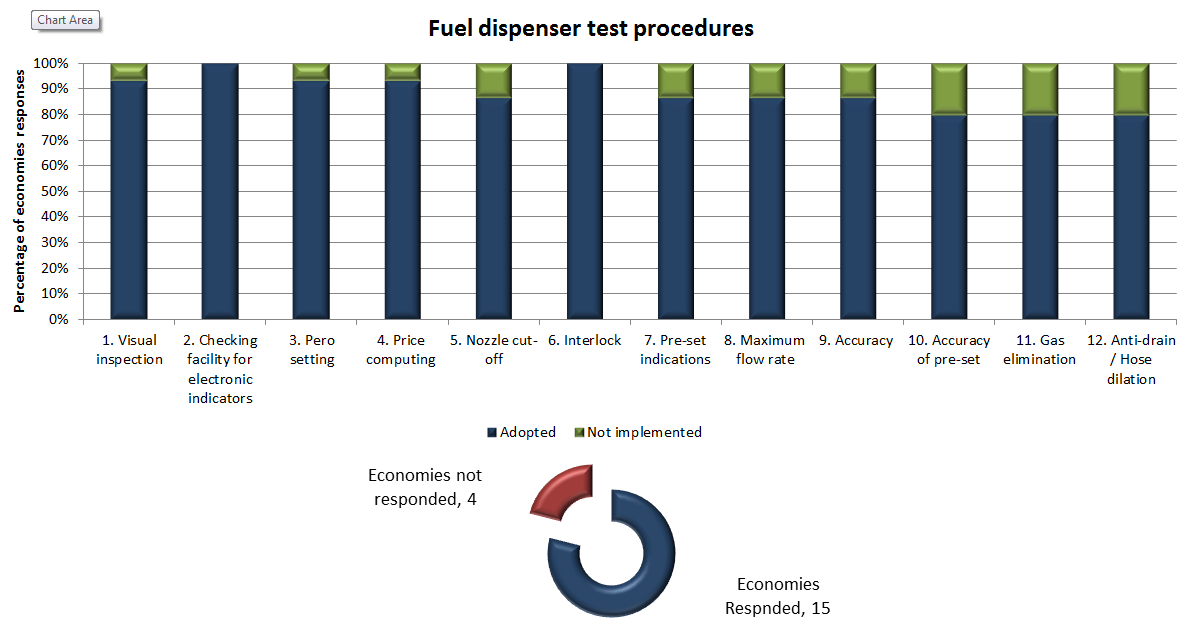

SURVEY RESULTS ON ADOPTING THE FUEL DISPENSER TEST PROCEDURES

The following results are from a survey completed in 2016.

Test name |

Total economies surveyed |

Adopted |

Not implemented |

Economies not responded |

1. Visual inspection |

19 |

14 |

1 |

4 |

2. Checking facility for electronic indicators |

19 |

15 |

4 |

|

3. Zero setting |

19 |

14 |

1 |

4 |

4. Price computing |

19 |

14 |

1 |

4 |

5. Nozzle cut-off |

19 |

13 |

2 |

4 |

6. Interlock |

19 |

15 |

Value |

4 |

7. Pre-set indications |

19 |

13 |

2 |

4 |

8. Maximum flow rate |

19 |

13 |

2 |

4 |

9. Accuracy |

19 |

13 |

2 |

4 |

10. Accuracy of pre-set |

19 |

12 |

3 |

4 |

11. Gas elimination |

19 |

12 |

3 |

4 |

12. Anti-drain / Hose dilation |

19 |

12 |

3 |

4 |

Economies who responded:

Australia, Cambodia, Canada, Hong Kong China, Indonesia, Japan, DPR of Korea, Malaysia, Mongolia, New Zealand, Papua New Guinea, Singapore, Chinese Taipei, Thailand, Vietnam

Australia, Cambodia, Canada, Hong Kong China, Indonesia, Japan, DPR of Korea, Malaysia, Mongolia, New Zealand, Papua New Guinea, Singapore, Chinese Taipei, Thailand, Vietnam